Applications

- Sort by

- Title A-Z

- Title Z-A

Monitoring Cooling and Lubrication Circuits in CNC Machines

Turck's FS121 offers flexible and cost-efficient monitoring for CNC machines, even in areas that are difficult to access

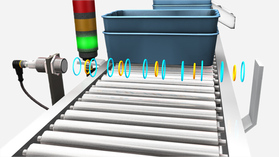

Preventing Package Jams in the Logistics Center

The CMMT magnetic field sensor proactively prevents downtimes in logistics operations. Learn more!

Control Cabinet Monitor for Transmission of Condition Data

Turck's IMX12-CCM control cabinet monitor and Beckhoff's Edge Device enable simple retrofitting for vitality data acquisition from control cabinets in the NOA data model

Efficient Cooling of Industrial Furnaces with Turck's FS+ Flow Sensors

Turck’s FS+ flow sensors ensure efficient cooling of industrial furnaces through real-time monitoring of flow and temperature

Condition Monitoring Sensor Automates Climate Control

Temperature and humidity monitoring in mobile chicken stalls

Cloud-based Remote Machine Maintenance

Special machine manufacturer Velco uses a remote monitoring solution based on Turck Cloud Solutions for locating error sources and monitoring production parameters

Cloud-based level monitoring

Battery-powered ultrasonic sensors wirelessly transmit data on lubricant levels to the Cloud

Preventive Maintenance on Conveyor Belts

Ultrasound reflection measurements offer an error-free and efficient solution for detecting the presence of objects on conveyor systems. The RU IP67 ultrasound sensor from Turck reliably detects objects.

No results

- Technologies

- Asset Monitoring Gateway with Cloud ID

- Asset Monitoring Gateway with SNAP ID

- Codesys

- Condition Monitoring

- Ethernet in Hazardous Locations

- Field Logic Controller

- Industrial Cloud

- Industry 4.0

- IO-Link

- Machine Safety

- Modular Machines

- Module Type Package

- Multiprotocol Ethernet

- Pick-to-Light

- Profinet

- RFID

- Snap Signal

- Sustainability

- TAS – IIoT Service Platform

- The Visual Factory